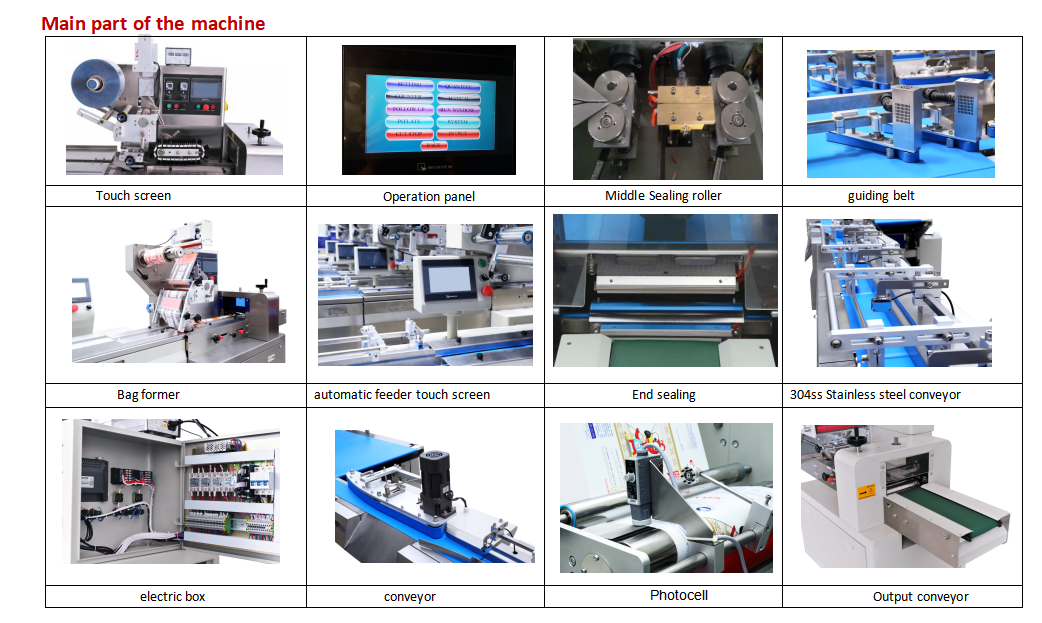

Automatic Feeding Packing Line details:

Main performance and structure features:

- Can be connected to the production line, making mass production fully automatic and efficiently possible, also products can be decanted onto the square table, which is convenient for various and small quality items production.

- The whole system is customized as per product, avoiding product been pressed and then out of shape. Products which stuck or fail in direction turing will be rejected to ensure constant and stable working of whole system.

- Speed adjustment is controlled by the inverter and servo driver . Speed phrase can be set as per customer request and product shape.

- Humanization design,easy and fast assemble and unassemble.

- Equipped with safe device, e.g. Electricity leakage protection, Emergency stop, Fault stop, Warning light,etc.

What is the product that our machine can pack?

- Food:cake, bread, meat muffin, biscuits, green bean cake, etc.